The zero-emissions L25 Electric wheel loader by Volvo Construction Equipment (Volvo CE) is building on its proven commercial performance with a host of upgrades that ensure further versatility, greater operator comfort and increased uptime.

Already demonstrating a reliability for matching superior strength with near-silent operation and zero exhaust fumes, the compact electric wheel loader is now being upgraded to ensure even greater versatility on the job site. The option to fit a new Parallel linkage, especially suited for medium-duty cycles and pallet-handling applications, will serve as a compliment to the existing Z-type one – delivering high breakout torque – but now for even more applications. And with an increase in the maximum speed up to 20 kph, the L25 Electric can move to the next jobsite much quicker.

Paolo Mannesi, Global Product Manager for Volvo Compact Wheel Loaders says: “Thanks to the results of a close collaboration with our dealers and customers, we are proud to reveal the next level in outstanding electric performance. With all these upgrades, the L25 Electric now boasts even greater comfort, productivity and uptime, making it a truly unique product on the market. Our electrification journey continues, and I cannot wait so see the next models reaching our customers."

The upgrades are building on the success of the L25 Electric in its initial iteration, which has already been proving popular with customers. Arvid Rüster, Product Manager at Berliner Stradtreinigung in Germany, says: “The L25 Electric is stronger than and more superior to its diesel brother. It is quieter and quicker to respond. The joystick control is also very sensitive.”

With operators reporting a more pleasant working environment with the emission-free wheel loader, they will no doubt appreciate that the upgraded machine is loaded with further features to enhance the operating experience. With reduced noise emissions thanks to a new hydraulic pump and the relocation of the Main Control Valve from the cab to the front frame – the machine will be even quieter inside and outside the cab.

For those operators working in more chilly climates, they can now easily choose the time and days of the week where they would like to arrive in a pre-warmed and defrosted cab, thanks to the new programmable cab heater option. And the need to reach under the hood to turn a main switch off at the end of a shift is now eliminated when using the machine regularly.

With increased comfort comes increased uptime, thanks to a new electric parking brake with hill-hold functionality – a convenient automatic feature for operators working on any construction site, but particularly on inclines or rough terrain. And because the disc-brake that was present in the former model is now replaced by a spring-applied and hydraulic-released wet-disk brake, related maintenance requirements are removed, helping to also cut costs and machine downtime. Operator comfort is also enhanced thanks to a more ergonomic joystick, the latest design on the market.

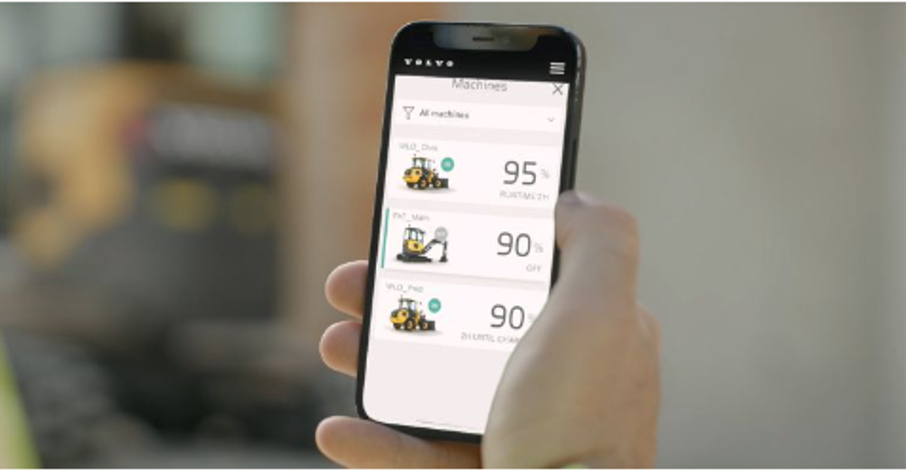

The time it takes to achieve a full charge from zero is now halved to only six hours with the improved 6kW on-board charger – if used with a 400V 16A CEE socket or public charging station. Speedier charging is always still available with faster off-board chargers 9.6 kW and 17.3 kW. And if combined with the newly launched Electric Machine Management Application (EMMA) customers can further boost uptime by keeping track of charging status, battery level and machine location, helping them to manage the charging process more efficiently.

All of these new features and improvements revealed as part of the updated L25 Electric wheel loader will be found on the new L20 Electric, available for pre-booking since October last year. The slightly smaller electric wheel loader offers a 1.8-ton payload and comes with Parallel-type linkage and a choice of 33 kWh or 40 kWh battery pack to accommodate various autonomy needs.

With versatility and sustainability in mind, Volvo CE is increasing its powerful range of construction solutions for customers across a range of applications. For those wanting to get a closer look at the updates to the L25 Electric, please take a look at our short walk around here.

| L25 Electric | L20 Electric | |

| Standard bucket capacity |

0.9 m3 238 gal |

0.8 m3 211 gal |

| Kinematics | P / Z | P |

| Tipping load (ISO/DIS 14397-1) |

3 450 / 3350 kg 7,605 / 7,385 lb |

3 050 kg6,724 lb |

| ...at full turn | 38° | |

| Breakout force |

37 / 54.5 kN 8,318 / 12,252 lbf |

35 kN 7,868 lbf |

| Hydraulic lifting capacity, max |

41 / 55 kN 9,217 / 12,364 lbf |

35 kN 7,868 lbf |

| Fork payload 80% |

2 100 / 2 000 kg 4,630 / 4,409 lb |

1 800 kg 3,968 lb |

| Dump height, max |

2 340 / 2 495 mm 7'8" / 8'2" ft in |

2 350 mm 7'9" ft in |

| Operating weight |

4 900 / 5 270 kg 10,803 / 11,618 lb |

4 550 kg 10,031 lb |

| Maximum travel speed - Standard |

20 km/h 12.4 mi/h |

|

| Battery capacity - Standard | 40 kWh | 33 kWh |

| Battery capacity - Optional | - | 40 kWh |

| On board charging time 400 VAC 16A | ~6 hours | ~5 hours |

| Off board charging time 400 VAC 32A | ~2 hours | |

| Indicative runtime | Up to 8 hours | |

Head of Brand, Marketing & Communication

Volvo Construction Equipment

Sales Region Europe / International

E-mail: anne.bast@volvo.com

Phone: 0735585906