Quality paving and fuel efficiency with Volvo's new all-rounder: the P6820C ABG

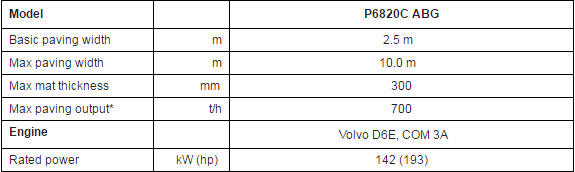

The new mid-sized Volvo P6820C tracked paver is an all-around paving solution that’s equipped for high performance — making it ideal for medium- sized jobs with some flexibility for larger- scale projects.

The P6820C is powered by Volvo’s D6E COM IIIA/EPA Tier 3 142 kW engine. The emission-compliant engine is considerably more powerful than the model it replaces, while providing lower fuel consumption and less noise. Fuel consumption is further reduced when the operator uses smart power mode, which lowers engine RPM to match power and demand — resulting in fuel savings of up to 30%. Reduced noise levels can also be attributed to sound lowering components and a robust frame. These features combined with smart power can dramatically decrease noise levels, compared with the competition.

Precise paving

The P6820C with a Volvo Variomatic screed offers a high degree of flexibility when frequently changing paving widths, up to twice the basic screed width — from 2.5 to 5 meters. By adding extensions, it can pave up to nine meter widths. With a Volvo fixed screed, the P6820C is proven to be effective when paving up to 700 tonnes per hour at 10 meters wide. The level of throughput makes the paver versatile enough for a range of applications, including municipal and main roads, highways and waste storage areas. It can also handle a range of materials, from wearing course and binder course to base course and frost protection layers. Paving efficiency is further aided by an optional front apron plate that directs material into the hopper, eliminating overspill in front of the paver. Independent, reversible hydrostatic drives, for both bar conveyors and augers, ensure the paving material is delivered evenly to both sides of the screed. The optimum head of material is maintained in the auger channel by adjusting the height, the speed and the direction of the augers. This larger volume of material and high throughput provide optimum mat quality regardless of width, thickness or paving speed.

The large hopper capacity promotes uninterrupted material flow for greater paving efficiency and quality and supports continuous paving, such as under bridges. The Volvo Variomatic screed, with its fast and efficient three-zone heating system also improves efficiency and quality. Volvo fixed and variable extending screeds produce high compaction levels, reducing time for subsequent roller compaction and resulting in a smooth high-quality mat. Volvo screeds can be used on bituminous and concrete material. Screed extensions can be added in minutes, without special tools, using Volvo’s quick coupling system.

Wired for productivity

The operator environment is ergonomically designed with an adjustable seat and affords the operator an all-around view that allows for more productivity. From the operator’s platform, a direct view into the hopper, the auger channel and the work area provides the conditions for achieving high-quality paving. The swiveling, tilting, extendable control panel features the newest Electronic Paver Management II system (EPM II), which controls all functions and guides the operator, step by step, through working functions.

Operators can select engine data menus in multiple languages via a large color screen. The EPM II also monitors fuel consumption and manages service intervals to alert the operator when routine maintenance is due. A settings manager reduces set-up times by allowing operators to save settings in the system for use when the machine operates in similar conditions in the future. For security, all electronic control panels, including the EPM II, can be removed and stored in a lockable compartment.

Wide contact area crawler tracks combined with good weight distribution allow effective transfer of engine power to the ground. The rubber pad-clad crawler units are maintenance free and feature individual electronically controlled drives for each track.

A system monitors track movement and controls motor response — ensuring both straight line and fixed radius work are accurate. These, combined with good weight distribution, ensure an efficient paving process. Smooth and precise control of the electro-hydraulic steering is gained via an easy-to-use dial on the control panel.

Maintenance of the P6820C track paver has been simplified, with improved service access from the operator’s platform to service points, via large opening compartments. An optional central lubrication system automates lube maintenance. A canopy that is quick and easy to fold down allows easy transport, too.

Volvo pavers are available with Care Kits, to guarantee longer life and better performance of wear parts, and customer service agreements (CSAs), which bundle service and maintenance offerings into comprehensive packages that cater to a variety of customer needs. And as with all Volvo products, the P6820C tracked paver is backed by an extensive service network that provides the peace of mind that comes with an extensive, worldwide infrastructure of technicians, workshops and dealers.

Specifications:

*depending on the mat thickness, the paving width and paving speed and can vary according to paving conditions of the jobsite.

Ends.

January 2016

For further information, please visit: www.volvoce.com/press Or contact:

Thorsten Poszwa

Director, External Communications

Volvo Construction Equipment

Tel: int + 32 2482 5021

Email: thorsten.poszwa@volvo.com

Twitter: http://twitter.com/VolvoCEGlobal

Brian O’Sullivan

SE10

London

Tel: int +44 77 333 50307

Email: osullivan@se10.com