Anteneh Gebremeskel, GPE Product Manager at Volvo Construction Equipment, explains the importance of proper tyre management and how the OEM’s Tire Pressure Monitoring System makes it easier and more convenient to keep tyres in optimum condition.

As construction companies and quarry operators strive for better efficiency, cost-effectiveness, and safety in their operations, one crucial factor that could be overlooked is the tyre pressure on their articulated haulers and wheel loaders. When these machines move, their tyres encounter rolling resistance, a force that opposes their movement, and the right tyre pressure plays a vital role in how well they perform on the job.

If tyres are underinflated, they have a larger contact area with the road, generating more friction and increasing the rolling resistance. This means the engine needs to work harder to overcome the resistance and consumes more fuel. In addition, the tyre carcass will be exposed to unnecessary loads, which causes premature failure. Overinflated tyres, on the other hand, wear prematurely in the centre of the tread pattern, leading to decreased tyre service life and operator comfort, as well as increased fuel consumption.

Furthermore, incorrect tyre pressure can pose a serious safety risk as underinflated or overinflated tyres make it more difficult to handle an articulated hauler or wheel loader. Traction and stability are decreased, braking distances are longer, and blowouts are more likely. This is when a tyre rapidly deflates during operation and can lead to a sudden loss of control.

To maximise fuel efficiency and safety, regular tyre pressure checks and maintenance following the operator's manual are essential. This straightforward step can save money on fuel costs and reduce the risk of accidents for everyone on site.

The pressure and temperature of each individual tyre is shown on a screen in the cab.

Check tyre status in real time from the cab

To make it easier and more convenient for operators to maintain optimum tyre pressure, we have included a Tire Pressure Monitoring System as an app on Volvo Co-Pilot with Haul Assist for articulated haulers and Load Assist for wheel loaders. The system, consisting of a transceiver and six tyre valve sensors, can also be fitted retroactively.

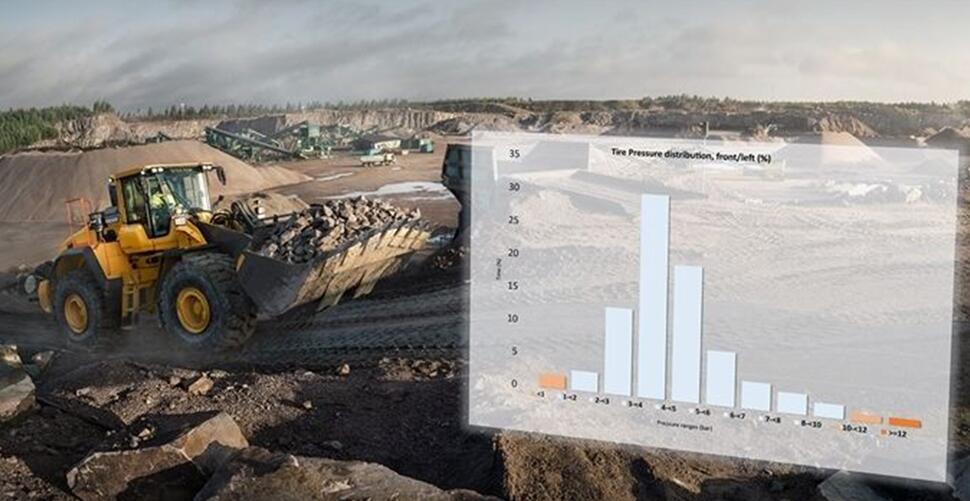

Tyre pressure and temperature are displayed in real-time on the screen in the cab. Each tyre is monitored independently, and pressure limits are set per axle. If any tyre deviates from the set parameters, the operator is alerted – alarm limits are displayed as nominal values and percentages.

A blue message lets the operator know there are inconsistencies in pressure or temperature and that the situation should be monitored, while an amber message indicates that these inconsistencies have worsened, and the operator must take action.

Tyre status data is also saved in the cloud.

Cloud-based insights for fleet and site managers

As well as being displayed in real-time, all data from the Tire Pressure Monitoring System is fed to the cloud and deviations in pressure or temperature are displayed as error codes in the CareTrack telematics portal. By reviewing and analysing trends, they can make informed decisions on tyre parameters based on similar site conditions.

Tyre pressure management is not just a maintenance chore; it's an essential aspect of construction equipment management that directly impacts operations. With our cutting-edge Tire Pressure Monitoring System, customers can conveniently benefit from increased safety, lower fuel consumption and emissions, enhanced operator comfort, greater uptime, and lower maintenance costs.