Wheel Loader vs. Excavator: Which is the best crusher feeder?

Key Takeaways

- The decision to use an excavator, wheel loader or both should be based on three critical factors: the type of material being handled, the jobsite layout and your production goals.

- High-volume sites with large material piles and fast cycles favor a wheel loader, while deep digging and accurate placement require the power and speed of an excavator.

- To maximize efficiency and prevent damage, operators should prepare the material by removing oversized pieces and foreign objects and maintain a consistent feed rate directly into the center of the crushing chamber.

So, how do you get material to the crusher? The choice often comes down to a wheel loader or an excavator — and sometimes, using both is the smartest move. There’s really no universal answer — the best tool for the job comes down to your specific materials, site layout and production goals.

Choosing the right loader is a big deal. An inconsistent flow of material can cause frustrating slowdowns or even bring your entire operation to a halt. A steady feed ensures a consistent particle size, which is essential for meeting tight specifications for things like road construction and concrete. On top of that, feeding your crusher at the right rate helps minimize wear and tear on components and prevents issues like bridging, where material clogs the opening and can cause damage.

3 Critical Factors When Selecting a Crusher Loader

When selecting the right machine for your operation, consider these:

- Material type: The properties of the material — rock versus sand, large versus small, hard versus soft and so on — will affect machine performance. Large, abrasive or hard materials require a heavy-duty machine like a large wheel loader or hydraulic excavator, whereas softer, more varied materials might suit a smaller-class wheel loader.

- Site layout and mobility: Your crusher’s location, haul distances, stockpile setup and available turning space are all important considerations. For instance, static crushers are often paired with larger, more robust loading equipment like excavators to handle continuous high-volume feeding. On the other hand, mobile crushers need smaller, more agile loaders for quick relocation.

- Production targets: These targets, which can range from high-volume continuous feeding to smaller, variable output requirements, should steer your decision. High-volume sites with large material piles and fast cycles favor a wheel loader, while deep digging and accurate placement require the power and speed of an excavator.

The Case for Wheel Loaders

Known for their mobility and versatility, wheel loaders are excellent for jobs like stockpiling and efficient load-and-carry operations. They can achieve faster cycle times over short distances and have the flexibility to tackle various tasks around the jobsite.

That said, wheel loaders do have some drawbacks. They offer less reach and precision than an excavator, which can be a disadvantage when you need to place material carefully into a hopper. They may also be less efficient for continuous feeding and can consume more fuel. Ultimately, wheel loaders are designed to excel at one thing: quickly scooping and moving large volumes of loose material from a pile to the crusher. Their productivity relies on their big bucket capacity and their power to handle bulky loads in fewer trips than an excavator.

Why an Excavator Might Be a Better Choice

When you need superior reach and precision, an excavator is hard to beat for placing material into a hopper. They’re also a smart choice for sites with limited operating space and are well-suited for a consistent feed that keeps your crusher running smoothly. Unlike wheel loaders, which are built for moving large, loose volumes, excavators offer the precision and reach needed to dig from a specific source. This is what gives them a faster cycle time for excavation tasks.

On the other hand, excavators are less mobile and flexible. They can’t move around the jobsite as easily as loaders and often need a dedicated support machine (like a truck or loader) to handle stockpiling and hauling materials.

Balancing Technology with Operator Expertise

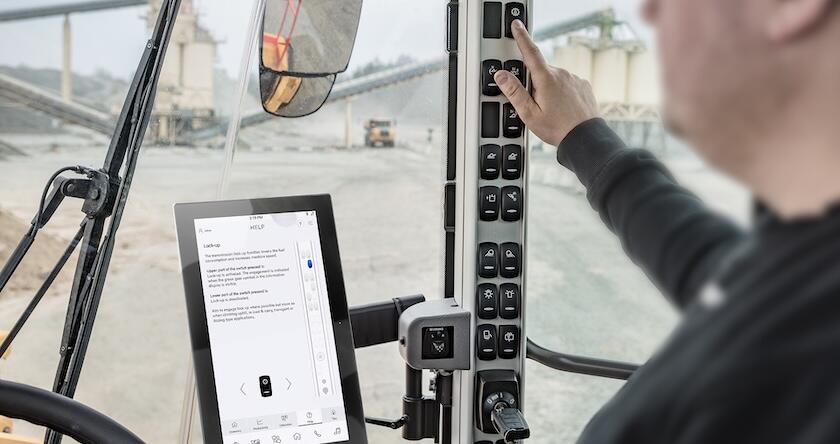

Today’s technology plays a significant role in optimizing crusher loading. Heavy equipment telematics is a great example, providing real-time data for remote monitoring of machine health, utilization and operational parameters. This data allows you to better manage production, track operator performance, improve maintenance scheduling and make smarter decisions about equipment deployment.

Matching a machine’s size and bucket capacity to the crusher is a common challenge. Oversizing equipment can lead to excessive wear and downtime, while undersizing equipment can increase cycle times and costs. It’s also crucial to consider your operator’s skill level. A skilled operator can monitor material conditions and machine performance in real time, adjusting feed rates and minimizing downtime. A less-experienced operator may need more training or assistive tech to achieve similar results.

Tips for Efficient Crusher Loading

Before material is loaded in by a crusher feeder, it should be prepared by removing oversized pieces, fines (or quarry dust) and foreign objects like metal and wood. To maintain a consistent and controlled feed rate, the operator should feed material directly into the center and ensure that the crushing chamber is kept full. Surge piles or bins also help regulate material flow.

It’s not uncommon to use both excavators and wheel loaders to feed crushers because they can complement each other for different tasks on the same site. For example, the visibility from an excavator’s high-rise cab is helpful for primary loading from stockpiles or demolition debris. Meanwhile, a wheel loader can handle the load-and-carry functions, moving material from stock or surge piles directly into the crusher.

Ultimately, the best choice comes down to testing and tracking performance to make a data-driven decision that aligns with your specific material, site and production goals. Taking the time to get this right can lead to increased productivity and lower costs per ton across your entire operation.

Be sure to check out our latest line of Volvo crawler excavators and next-gen Volvo wheel loaders if you’re in the market for a new crusher loader for your aggregate quarry.

Eric Yeomans

Product Manager – Large Wheel Loaders

Eric has spent several decades with Volvo and Volvo dealerships in a variety of roles including customer support management, telematics management and product management positions. Today, he represents regional wheel loader requests by providing product training, support and design input.