Buying an articulated hauler – 13 things to consider during the demonstration

When you’re ready to purchase an articulated dump truck, whether it’s your first ADT or an addition to an existing fleet, be sure to get input from your entire team. Owners and fleet managers usually have different input compared to operators and service team members.

It’s important to find a reliable hauler that can move the most material at the lowest cost, but there are several other factors to consider, so you have the right hauler for the type of work you’re doing. These tips can help during an articulated hauler demonstration with a dealer.

Articulated hauler demonstration tips for owners and fleet managers

#1 – Total Cost of Ownership (TCO): While the initial price of an articulated hauler is important, it’s only one factor to determine how much a hauler can impact your earnings, plus what it will likely cost you to get the work done. Most dealers and manufacturers can help you determine the TCO of an articulated hauler on your jobsites. Make sure the hauler you end up selecting will give you the biggest ROI for the time you intend to keep and run it.

#2 – Fuel Efficiency: If you can get the same amount of work done and burn less fuel doing it, that should be a deciding factor. Over time, excess fuel consumption can be eaten away at your profits. As a part of evaluating TCO, ask about fuel-saving features that cut back on consumption.

Another feature to point out is our Volvo Automated Traction Control system (ATC), which consists of a number of sensors that control the differential locks with signals to the machine’s electronics (ECU). These sensors immediately sense the slightest wheel slip and engage the needed drive combination automatically. This means you’re always running your hauler with the right drive combination, allowing you to move more tonnes per litre. The Volvo drivetrain also includes Terrain Memory. This intelligent function identifies and remembers slippery road segments.

#3 – Safety: When evaluating an articulated hauler during a demonstration, make sure safety is a core part of the assessment. Look for the following machine and jobsite safety features:

- Visibility: Check for a clear field of view from the cab, including sleek hood and cab lines and camera systems that provide additional awareness around the machine. Easy-to-use in-cab displays for managing camera views are also helpful.

- Lighting: Good lighting is essential for early mornings, late evenings, and shaded areas. Exterior ambient lighting, illuminated entry points, high-mounted work lights and lighting inside service compartments can improve visibility for both operators and ground personnel.

- Collision Awareness: Modern proximity-detection systems can alert operators to nearby vehicles, obstacles or pedestrians. Some systems also provide automated intervention.

- Safe Access and Servicing: Ensure the machine has safe entry and exit points with well-positioned steps, railings, and lighting. Ground-level access to key service points can reduce climbing and the risks associated with working at height.

- Harness Anchor Points: Certified harness anchor points to support fall-prevention are recommended to align with safety standards such as ISO 14567:1999, helping meet regulatory requirements on worksites.

Compare all our articulated hauler models

#4 – Cycle Times: How long does it take to get from point A to B and back? That’s an important number to know when looking at a new articulated dump truck. Look for features like Volvo Dynamic Drive, which allows our haulers to accelerate quickly by being able to skip gears to get to max speed faster.

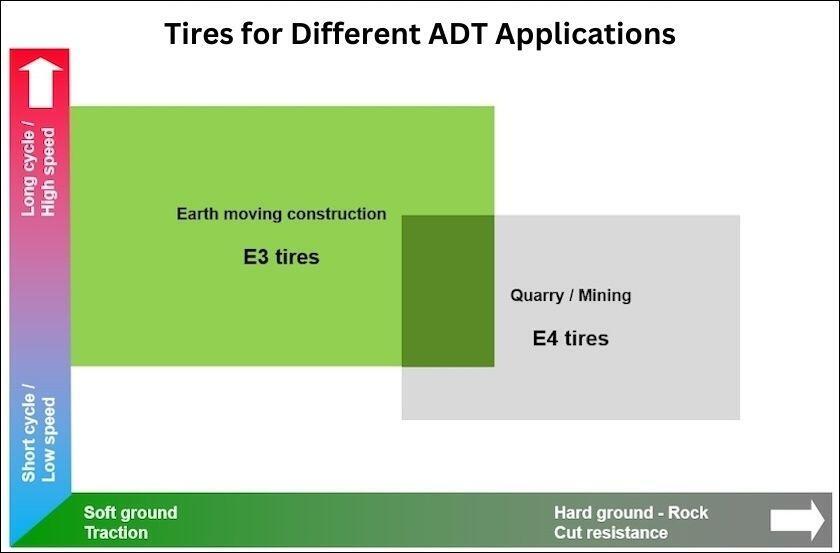

#5 – Matched Tires for the Application: It’s critical to ensure your hauler has the right tires for your specific application. When considering E3 tires versus E4, for example, be sure to look at more than the ground conditions. You should also consider the distance you need to travel. The chart below is a good quick reference.

Also, each tire manufacturer has a rating on them called TKPH (tonne kilometer per hour), which is the maximum recommended load the tires can carry at a particular speed. An easy way to explain this is that a tire needs time to cool down. If you’re doing very long runs (more than 1 km) at high speeds, rigid haulers might be a better match because their tires can dissipate heat faster than ADTs. The tires on an articulated hauler are meant more for rough terrain than nice, hard-packed roads.

Another ADT tire consideration is whether or not you should use standard 29.5 tires or consider putting on a set of 875 tires. The 875 tires are wider and can provide less ground pressure by distributing the weight over a larger contact point on the ground, giving the hauler more flotation in really poor under footing conditions.

#6 – Material Density: The old saying goes, “What weighs more, a ton of feathers or a ton of bricks?” Both weigh the same, right? But what’s the volume it will take to get the capacity to be efficient with the hauler? Be sure to look at material volume versus weight before selecting a new hauler.

As an example, are you maximizing every load with a 42-tonne hauler, or are you only getting 30 tonnes with each load? This is important to know because you may need factory-fitted options like a spill guard or sideboard extensions to add more volume to your hauler.

Another thing to consider is a tailgate. At Volvo we have multiple tailgate versions, but the most popular is our overhung option. If you’re hauling large rocks and worried about them getting stuck in the tailgate, an underhung version might be a better solution so you can get maximum payload out of each load.

#7– Material Type: It’s also important to consider the type of material you’re planning to haul. Is it sticky? If so, find out if your hauler comes with a bed heat option. Is it abrasive? If so, you might want to add factory liners to extend the life of the bed. Be sure to ask about these types of options depending on what you’re hauling.

Articulated hauler demonstration tips for operators

#8 – Comfort with Easy Access to Controls: A good articulated dump truck will have a simple cab with set-it-and-forget-it controls. Be sure to look for optimized control features like downhill speed control, cruise control and optimized braking features like the Volvo OptiShift with reverse-by-braking (RBB).

#9 – Automatic Drive Combinations: Automatic drive combinations, like our unique 6×4 drive combination, can improve performance and comfort, plus the TCO of the hauler over its life. By being in 6×4 mode, for example, you don’t burn as much fuel or have nearly as much tire wear. 6×4 is the best option if your jobsite has nice, hard-packed roads with flat runs.

#10 – In-Cab Machine Control Apps: Even the best operators can use an assist from time to time. Ask if the hauler you’re looking at includes an in-cab monitor showing critical information such as tire pressure and the capacity of each load, e.g. on-board weighing.

Some OEMs like Volvo also provide a maps app that allows you to see the other haulers, even vehicles and people, on the jobsite too.

Articulated hauler demonstration tips for service managers and mechanics

#11 – Service Access: Make sure the haulers have long service intervals and that service access is easy. This will help you experience less downtime. On Volvo ADTs, for example, there’s no daily or weekly maintenance on our haulers. You don’t have to grease our haulers until 250 hours and there’s a 1000-hour engine service interval (for Stage V machines).

#12 – Telematics Support and Machine Monitoring: Make sure your articulated haulers give you access to telematics data. That way you’ll for example know if your operators are utilizing a delayed engine shut down feature and if they’re correctly using the retarders versus using the service brake. Using information like this can save you a lot in unnecessary downtime and/or costly repairs.

Some machine providers offer 24/7 machine monitoring, supplying performance reports and notifying when preventive maintenance action is required. An app on your mobile device can make it even easier.

#13 – Common Service Parts: If you run a fleet of different machines, you should check to see if the new haulers have the same parts as your existing equipment. Common parts like filters and hoses make service much faster and easier. With Volvo, for example, an L220 wheel loader, an EC500 excavator and an A40 truck all run Volvo D13 engines, so all the filters and a majority of the engine parts are common, making routine maintenance a much simpler process.

For your next articulated hauler demonstration, be sure to prepare and take checklists that your team can use to evaluate the hauler thoroughly. Getting a holistic view from key roles can help make sure the articulated dump truck you ultimately go with will help you maintain or increase productivity, maximize efficiencies and keep crews safe on your jobsites.