Full speed ahead in the quarry: Sebald Zement relies on the Volvo EC530E excavator

Sebald Zement is a family-run company with a long tradition that has been firmly rooted in the region for six generations. At the main site in Hartmannshof in Middle Franconia, idyllically situated in the Hersbrucker Alb, around 100 employees work together across administration, technology and production. The company not only stands for high-quality cement products, but also processes gravel, limestone and dolomite into, for example, high-quality fertilizer granulate.

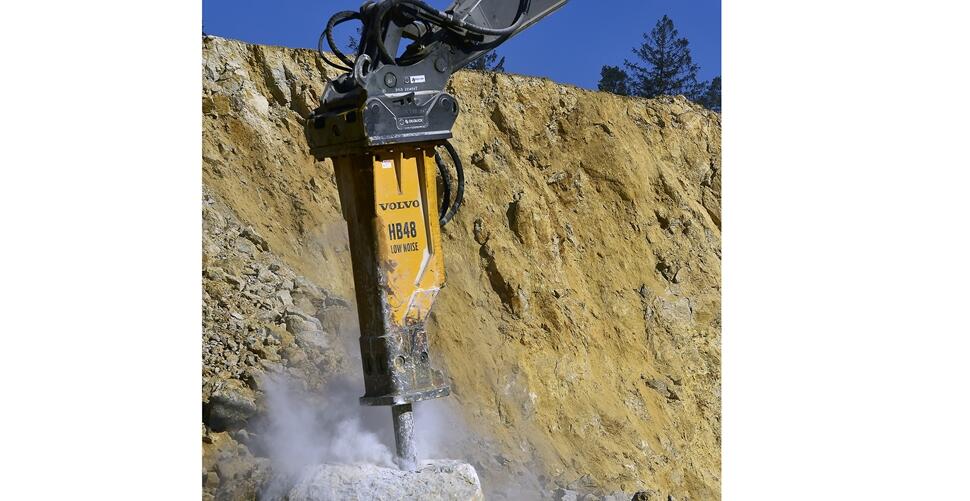

With the new Volvo EC530E, a real high performer has now joined the fleet: a 50-ton tracked excavator with a quick-change system and hydraulic hammer – and at the same time the first excavator ever in Sebald Zement's fleet. The acquisition marks an important milestone in the quarrying process.

Florian Forster, Sales representative at Robert Aebi, recalls: " Originally, we had a wheel loader in use for demonstration purposes – but in discussions with the customer, it quickly became clear that an excavator would be a much better solution for the requirements in the quarry. The EC530E was the perfect fit – both in terms of performance and handling. The feedback after the demonstration was consistently positive, so the decision to purchase was made very quickly."

More efficient, more flexible, more economical

The introduction of the Volvo excavator has fundamentally changed daily work in the quarry. Where previously large chunks of stone had to be laboriously sorted out by a wheel loader after blasting and then stored for weeks before being crushed later by an external service provider, the EC530E now performs this task directly on site – and much more quickly and efficiently.

Technical Operations Manager Maximilian Spieß describes the advantages from the company's perspective: "With the new excavator, we can not only process the entire blasting shot directly, but also optimally feed our systems at the same time. The oilǪuick quick coupler makes it possible to switch between bucket and hammer within a very short time. This gives us enormous flexibility and increases throughput in processing.”

The team was particularly impressed by the factory's own Volvo breaker, which works in perfect harmony with the EC530E. Despite its immense impact power, it works surprisingly quietly – a real plus given the proximity to the site. "The breaker is not only powerful, but also surprisingly quiet. This is an important argument for us, especially outdoors, as we want to disturb our neighbors as little as possible," explains Spieß.

Investment with a view to the future

The purchase of the Volvo EC530E excavator was much more than just a machine decision – it was part of a comprehensive change process at Sebald Zement. With the generational change in the company management and the new appointment of Jochen Pohl as quarry manager, many things were rethought internally. Work processes were analyzed, potential for improvement identified and the team actively involved in further development.

"We deliberately took the time to scrutinize existing processes and work with our employees to consider how we can work more efficiently and sustainably," explains Technical Operations Manager Maximilian Spieß. "The new excavator is the result of a whole series of tests, comparisons and discussions – and the feedback from the team was clear: this is the right machine for us."

Another key factor in the decision was the close and reliable cooperation with sales partner Robert Aebi. From the first meeting to commissioning, it was not only the technology that impressed, but above all the teamwork.

"Advice, service, support – it was just perfect," says Spieß. "We always had a contact person, regardless of whether it was about technical details, special conversions or service issues. The exchange with our permanent service technician also ran smoothly – a really good collaboration, both professionally and personally."

Machine operator Hans Renner, regular driver of the new excavator, sums it up perfectly: "The EC530E is great to drive. Operation is intuitive, the display is easy to read and maintenance is simple. When chiseling, you clearly notice how well the seat is cushioned in the cab. You sit comfortably - that makes all the difference in everyday life."

Machine operator Hans Renner, regular driver of the new excavator, sums it up perfectly: "The EC530E is great to drive. Operation is intuitive, the display is easy to read and maintenance is simple. When chiseling, you clearly notice how well the seat is cushioned in the cab. You sit comfortably - that makes all the difference in everyday life."

Conclusion: A strong overall package

With the Volvo EC530E, Sebald Zement has not only opened a new chapter in quarrying practice, but has also set a strong example for investment with foresight. More efficient, quieter and more flexible - and with a partner, Robert Aebi, who supplies everything from consulting to service from a single source.

Journalists wanting further information, please contact:

SANDRA JANSEN

Media Relations & Communications Manager - Region EU/INT

Volvo Construction Equipment Germany GmbH

E-mail: sandra.jansen@volvo.com