The Advantages of Digital Documentation in Construction and Mining

Key Takeaways

- Digital documentation tools directly solve common jobsite frustrations like lost documents, version control issues and slow information flow.

- Implement digital solutions to get instant insights into equipment performance, site conditions and project progress, empowering smarter decisions.

- Embrace digital transformation in construction and mining to streamline workflows, enhance planning and secure a competitive advantage.

Even in today's increasingly digital world, there's still a lot of paper documents — or the equivalent of that electronically with PDFs, online RFPs and things like that. Either way, that can create real challenges to organization, efficiency and accuracy. While it's been the established method for generations, rapid advancements in technology mean there are now better, more streamlined ways to manage your critical information.

The Problem with Paper

Think about it:

- Version Control Nightmares: Is that the latest report, or did someone print an older version? With paper, knowing you’re working with the most current document can be a struggle.

- Delayed Information: Paper documents move at the speed of a human hand. If a change order needs to get from the site to your office, it takes time, delaying decisions and potentially causing rework.

- Room for Error: Manual data entry from paper forms can lead to transcription mistakes, making everything from payroll to material reconciliation a headache.

- Accessibility Challenges: Need to check a detail from a project two years ago? With paper, you might have to sift through boxes or binders. Information locked away in physical files isn’t readily available when you need it most.

The Benefits of Digitization in Construction and Mining

The good news is that digital documentation is now much more prevalent, offering a powerful solution to these challenges and transforming how information is managed on and off your jobsite. By moving to digital systems, you can gain significant advantages in efficiency, accuracy and overall project control. There’s an investment — but for most contractors, it’s worth it.

Imagine a world where data flows seamlessly from your equipment to your office, providing real-time insights rather than after-the-fact guesswork. Many heavy equipment manufacturers are integrating solutions that help make this a reality.

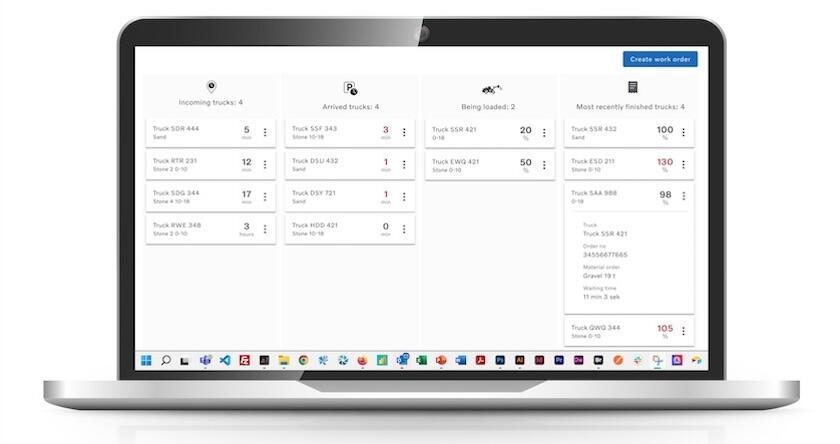

For example, solutions like Connected Load-Out allow for the complete digitalization of the loading process. Instead of handwritten load tickets that can get lost or misread, work orders and load tickets are sent automatically and securely from the machine cab to your site office. This drastically cuts down on paperwork, minimizes communication errors and gives you an immediate overview of operations.

Starting Your Digital Journey

It's completely normal for the idea of a digital transformation in construction or mining to feel overwhelming, especially when you hear about advanced tech like AI. But remember,: you don’t have to go from zero to fully digital overnight. You can grow step by step, making small, impactful improvements that will still benefit your company significantly.

Many digital tools are designed to be user-friendly and web-based, similar to the computer and browser applications you might already use every day. Plus, your equipment might already be prepped for it — many modern machines come prepared with the necessary software from the factory, allowing services to be activated from the cloud on the backend.

The key is to start with your biggest pain points. Here at Volvo, we guide you through this digital transformation, recommending the right solutions to improve your operations based on what challenges you’re facing today. It’s about finding the right fit for your business, not just implementing technology for technology’s sake.

Enhanced Oversight and Better Planning

Digital systems don’t just streamline existing processes — they open up new possibilities for how you manage your operations and plan for the future. Here are a few more examples of the types of solutions I’m talking about.

Let’s start with Connected Map. It offers a visualized, real-time overview of your entire site by extracting positioning data from machines and vehicles. You can see exactly where all connected equipment and personnel are, making it easier to communicate site changes, monitor progress and ensure safety without relying on radio calls or manual check-ins.

When it comes to understanding your site, machine and operator performance, a system like Performance Indicator can collect data from your equipment and upload it to a cloud-based platform. This means instant insights through customizable dashboards on things like production rates and fuel efficiency. You can quickly identify areas for improvement, troubleshoot issues as they arise and make data-driven decisions to optimize your fleet’s output.

Even before an attachment hits the ground, digital tools can make a huge difference. One final example is our Site Simulation software that can take jobsite-specific factors — like material density and ground conditions — and combine them with equipment data to run powerful projections. This helps in pre-planning, providing accurate forecasts for costs, budgets and bids, and even helping to visualize how different operational approaches will impact your productivity. It’s about making informed decisions before you commit resources.

Why Your Jobsites Need to Go Digital

Digital documentation is a fundamental shift that helps your business operate more efficiently, reduce errors and gain a competitive edge. It’s about leveraging technology to ensure that every piece of critical information is accurate, accessible and actionable, empowering you to manage projects with greater confidence and foresight. If you’re still relying heavily on paper, it might be time to explore how going digital can transform your operations for the better.

Digital documentation is a fundamental shift that helps your business operate more efficiently, reduce errors, and gain a competitive edge. It's about leveraging technology to ensure that every piece of critical information is accurate, accessible, and actionable, empowering you to manage projects with greater confidence and foresight. Embracing digital documentation is a cornerstone of connected construction, allowing you to integrate data across your entire jobsite for enhanced control and insight. If you're still relying heavily on paper, it might be time to explore how going digital can transform your operations for the better.

If you have questions about going digital, your local Volvo dealer can answer them and recommend the right solutions to get you going.