How to Select the Right Mini Excavator Dozer Blade Attachment

Key Takeaways

- There are three primary types of dozer blades to consider for your mini excavator — standard, angle and floating — each with their own advantages.

- Six-way dozer blades are another option for added versatility and precision, but they may require a bit more maintenance compared to the three options above.

- Evaluating the types of tasks you perform most often will ultimately determine the most suitable dozer blade or even highlight the need for a different attachment altogether.

Let’s take a look at the three primary types of dozer blades, their respective advantages, and other options to consider if you’re currently looking for your next compact excavator.

Types of Dozer Blades for Mini Excavators

Standard Dozer Blades

A standard dozer blade (shown in the header image of this article) may also be called a straight blade or an S-blade. It has a flat, straight edge. In addition to providing stability, it can be used for general grading tasks like stripping topsoil and shaping hard-packed surfaces. This blade is sturdy and does a nice job absorbing shock. Typically, it only moves up and down. Because the straight blade doesn’t have side wings (hence the nickname), it’s not the best option for handling looser material that you don’t want to push out to the sides.

Angle Dozer Blades

Just like it sounds, an angle dozer blade can be hydraulically angled to the left or right from its pivot point, allowing you to push material to one side rather than straight ahead. This option is good for tasks like side-casting (moving material out of the way), backfilling trenches, shaping slopes, clearing land and leveling uneven surfaces.

Floating Dozer Blades

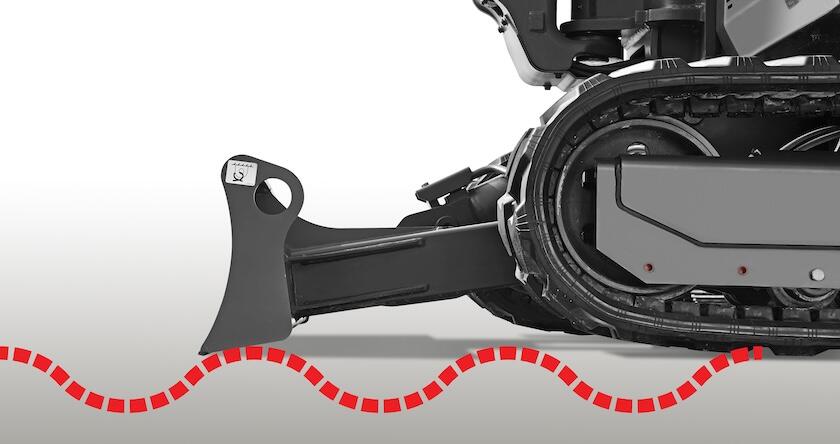

The floating dozer blade feature is more about the functionality than the blade itself. In fact, depending on the manufacturer, it may be an option for more than one type of blade. Typically, this mode is activated from the machine controls. The blade then automatically positions itself to "float" just above the surface and follow the contours of the ground. This makes it ideal for back dragging and fine grading tasks.

These first three blades are commonly found on a range of excavator sizes. For example, all of our Volvo compact excavators come with a standard blade, the 3.7-ton EC37 through the 6-ton EC60 have an optional angle blade, and the EC37 through the 8.8-ton EC88 have an optional floating blade.

6-Way Dozer Blades

For added versatility and precision, there’s also a six-way dozer blade that can move up and down, tilt left and right, and angle left and right. A strong pivot point and hydraulic tilting make this blade ideal for more exact contouring and shaping. Six-way blades have some additional maintenance considerations, though. You’ll need to keep an eye on its greaseable pins and bushings as well as hose springs that prevent the hydraulic hoses from being pinched.

Machine Controls and Dozer Blade Selection

The machine’s controls also come into play when evaluating dozer blades. Some mini excavator manufacturers make dozer blades even more intuitive with a dedicated joystick. Here at Volvo, our dozer blade control lever is very intuitive — it’s separate from the controls to run the rest of the machine. Ergonomic controls like ours can include preset functions like blade float, blade angle or high/low travel speeds to make working with your blade even easier.

So, the next time you're considering a mini excavator or evaluating your current fleet, don't overlook the dozer blade. Think about the types of jobs you're tackling: Are you doing a lot of fine grading? Do you need to move material quickly? Answering these questions will help you choose the best blade for the type of work you’re doing — or, you may even determine you need a different mini excavator attachment altogether.

If you need additional advice, just reach out to your local Volvo dealer and they can discuss your options and find the perfect match for your needs.

Darren Ashton

Product Manager – Compact Equipment

Darren was raised in a rural area in Saskatchewan and has been around equipment since an early age. After initially working in road construction, he moved to the heavy equipment industry in various management roles for over 30 years. Today, he represents Volvo compact equipment requests by providing product training, support and design input.